A busy auto repair shop doesn’t always mean a profitable shop if there is staff chaos behind the scenes.

The secret to a successful shop lies in getting a good workflow between the front counter and the back bays. When every step of a process goes smoothly, your staff is empowered to do their best work with far fewer delays.

Here’s the thing. It’s highly likely that a shop with a smooth process has figured out how to shave minutes off the time it takes to do each estimate and get a repair done. When you are saving time across your shop workflow, it makes it easier to produce more profit in a day. But how do you break down the numbers to find the right balance?

What eats into your profits?

According to Automotive Training Institute coach Charlene Parlett, the top 5 profit eaters for auto repair shops are:

- Not knowing your numbers

- Pricing policies that don’t work

- A lack of defined expectations

- High daily car counts

- Staying with the status quo out of a fear of change

She cites a 2017 Ratchet + Wrench survey that found 1 in 3 shop owners were too busy to track their key performance indicators. Yet, every shop should measure:

- Total sales for parts and labor

- Total costs for parts, labor wages and service advisor wages

- Gross profit (total sales minus total costs)

- Billed labor hours per technician

- Clocked hours per technician

In addition, she advises shop owners to stop “winging” parts pricing — doing so leaves money on the table. Too often, shops undercharge on parts and have to work longer hours to hit their projected revenue.

Instead, Parlett tells shop owners and managers that “productivity equals profits.” Once shop employees know what level of performance is expected of them and are given clear goals, they have something to work hard to hit. This means they know their responsibilities, their target for billable hours, and how their work is measured.

Increasing the volume of vehicles in for repairs is also not the way to a profitable shop. Shops with the highest profit margins strike a balance between maintenance and repair work, not multiple heavy repair jobs.

Finally, she states that fear of change kills innovation and profits. As costs rise, shop owners need to adapt to survive. That may mean raising prices, reducing expenses, changing how people work, and adopting modern software technology.

How Fast and Easy Parts Procurement Drives Profits

Auto shops are not only selling their in-house services — they are selling their time. If you do not track where you win and lose labor hours (and ultimately dollars), you are losing the opportunity to make changes.

Sourcing parts via the phone or with multiple web pages open across multiple vendors sucks up labor time. The PartsTech Time Savings Calculator shows you how the hours saved during parts procurement equals thousands of dollars each year. Once you plug in your numbers, you may be shocked by what you see.

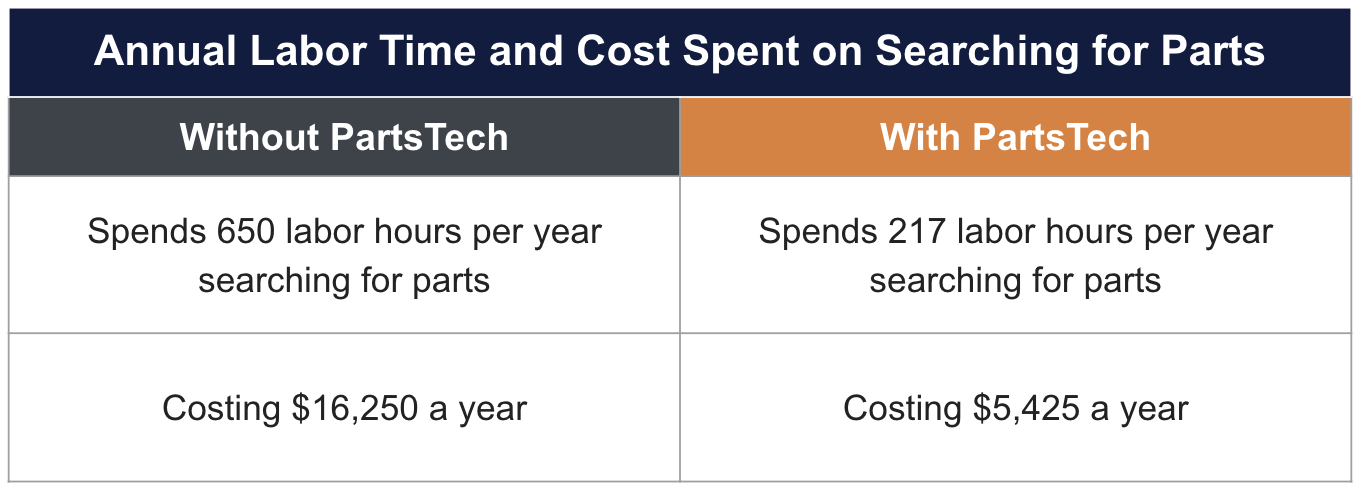

In a survey, PartsTech customers shared that they save between 5 to 15 minutes on parts ordering on EVERY repair order. Let’s average that out to 10 minutes per work order. Let’s take a look at a mock scenario to understand time savings:

- Number of vehicles serviced per day: 10

- Minutes spent searching for parts without PartsTech: 15 minutes

- Minutes spent searching for parts with PartsTech: 5 minutes (15 min. minus 10 min.)

- Hourly rate of service advisor: $25

- Number of days open per week: 5 days

Here’s how the numbers shake out:

In this mock scenario, PartsTech saves the shop 433 labor hours or $10,825 per year.

In short, when you save time, you use less labor and make more money.

If your shop could save 10 minutes on parts ordering per repair order, what would your annual labor cost savings be? What else could you do with that time and money?

Digital Transformation is Worth Trying

We invite you to take a leap and say “no” to chasing down parts by phone or with multiple vendor tabs open. When you speed up your parts search, you waste less time and earn more revenue.

If you are feeling overwhelmed by the idea of adopting digital solutions for your entire auto shop, starting with an online parts procurement tool is a great way to dip your toe into the water.

Shift your parts procurement strategy to PartsTech’s digital platform and find all of your parts in one place, fast. Don’t take our word for it — Hear how PartsTech has helped Lynwood Tire & Auto Service:

Sign up for a free PartsTech account to be connected with over 30,000 distributors, more than 4,500 brands, and tens of millions of parts. Watch your shop begin to transform.

Contact us to find out how to make the most out of every minute in your shop.