Just last year, auto shops could hardly get their hands on an adequate stock of oil filters due to significant supply chain shortages. Sourcing more complex parts for major repairs was even more challenging. Having (or not having) the right parts at the right time directly impacted a shop’s revenue. As a result, shops started ordering more parts than needed to stock up.

This trend created three problems:

- Hoarding of supplies to the detriment of other shops

- Spending beyond their parts budget “just in case” they needed certain items

- Creating clutter and/or extra expenses on warehouse costs

As the parts supply chain slowly improves, how can you make sure you are not overspending on parts while also ensuring you have what you need? What lesson can you learn from experiencing supply chain shortages to help you to be smart with your inventory moving forward?

The Events of 2020-2022 Accelerated a Transformation in the Auto Repair Industry

In March 2020, the world suddenly demanded contactless experiences, and the best way for businesses to meet this demand was to turn to digital solutions.

Auto shops began integrating digital technology, such as a shop management system, into every part of their business operations and shop workflow — from scheduling, estimate creation, work order approvals, payments, customer communication — and even inventory management and parts ordering.

So, what’s the lesson learned? Adopting digital solutions will transform your auto shop — in a very good way!

Let us explain.

Shifting Your Shop to Digital – Don’t Let It Scare You

Although shifting your shop from paper and pen to digital tools may seem daunting at first, the shops that have taken the leap have seen a positive, fundamental change.

This change spans not only how they interact with their customers but also in the habits of their shop staff and the overall approach to their shop operations. With that, one of the largest shop pain points — parts procurement — has become easier and more refined with digital tools.

We understand that the idea of shifting your auto shop to run on digital tools can be overwhelming. With this in mind, we’ve put together a 5-post blog series to help you wrap your head around turning to digital solutions just for parts procurement.

Let’s start by looking at some numbers.

Real Shops Share Real Outcomes from Online Parts Procurement with PartsTech

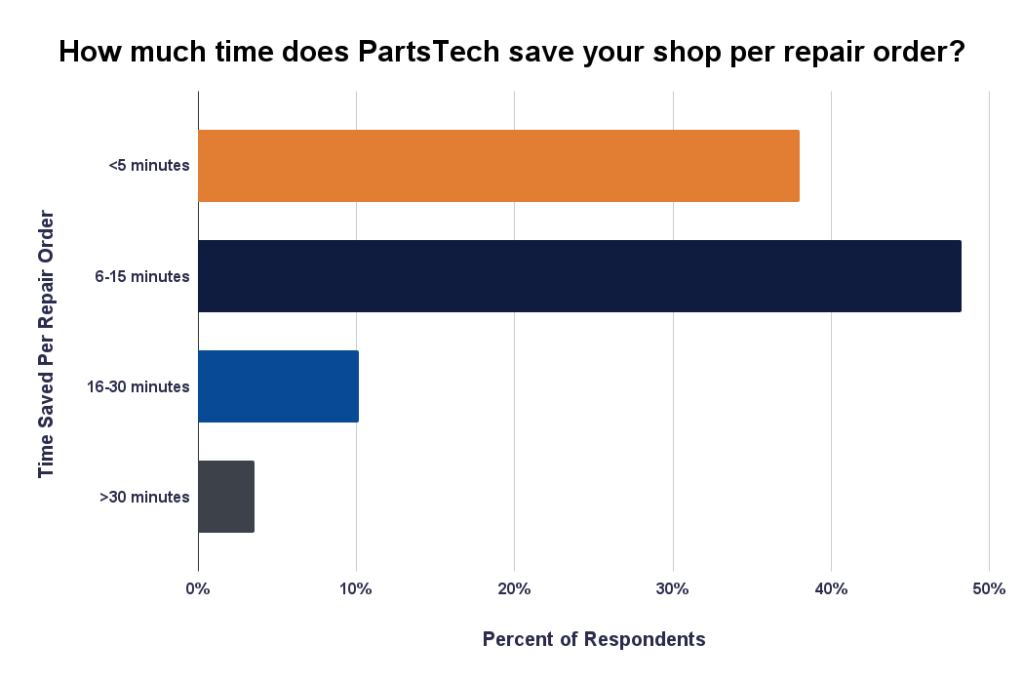

In October 2022, we surveyed 400 PartsTech users across the United States to better understand how they procure parts for their shops.

One question asked: “How much time does PartsTech save your shop per repair order?”

The results show that the majority of shops using PartsTech save themselves 5-15 minutes (let’s average that out to 10 minutes) per repair order.

If your shop saved 10 minutes on parts procurement per repair order, how much time would your shop be saving each week, month, or year?

One PartsTech customer quantified the time savings from a different viewpoint:

“[PartsTech] reduced phone time with vendors by 80%.”

– TeeKee C., General Manager

By procuring parts through an online site that allows you to pull all of your parts vendors into a single search window, you not only save hours of time that can be invested in other areas of your business, but you will also reduce much of the aggravation and headaches that are tied to ordering parts.

Open a free PartsTech account today.

When you adopt software for parts procurement, you’ll overcome the three biggest issues related to parts ordering: assessing availability, training staff, and keeping a healthy inventory. Read the next blog post in this series.