We invited PartsTech customer, Lauralee (Lola) Schmidt, COO at Schmidt Auto Care, to share her expertise on the importance of processes in auto shops. Lola offered invaluable insights into why auto shops need to create processes for their business and tips for getting started. If you missed it, we encourage you to take the time to watch the on-demand version of the webinar to hear Lola’s story of why she chose to make extremely tough decisions for the sake of saving her and her husband’s shop through process definition.

A Bit About Lola

Lola entered the auto care industry nine years ago when she married her husband, Erich Schmidt, Owner of Schmidt Auto Care in Ohio. She previously had a successful career with Estée Lauder™, where she lived and breathed the creation, implementation, and adherence to processes. When she started working with her husband on their auto shop business, Lola openly admitted, “I ignored all I knew, and we almost lost it all.”

It wasn’t until Lola and her husband nearly lost their auto repair business that Lola chose to take everything she knew about the power of processes in the cosmetic industry and apply it to their auto shop. A lot of time was spent, and hard decisions were made, but the payoff has been high.

Through processes, Lola and Erich turned their shop into a thriving, healthy business in just one year. Because of this, Lola is passionate about encouraging shop owners, new and seasoned, to build processes for their shops and stand by them.

Why Processes Matter

If you run a shop, Lola first encourages you to translate the word “processes” into “business practices and definitions.” She also acknowledges that no one likes process, but everyone needs it because defining your business is critical. “I would bet right now that a lot of you have opportunities inside of your shop to button up some processes,” says Lola, “and when you do that, it’s going to be painful in some way to your team or you, but in the long run, it will be better. You need processes in your shop because you need to define your day-to-day workability inside your shop – this removes all the chaos out of your shop.”

When you define your business and put processes around everything, you create clarity for your entire team. Lola points out: “When everyone knows what’s expected of them, they’re not just employees; they’re team members who feel valued and empowered.” On top of this, if you ever have difficult conversations with employees who are not performing, you can always point them back to the defined processes — the standards by which they agreed to when they signed the offer letter to work for you.

Getting Started with Defining Your Shop Through Processes

Here’s a high-level summary of the rich guidance that Lola provided to get you started in creating processes in your shop.

- Figure out what processes you need to define.

You should have a process for every nook and cranny of your business. Lola buckets the processes in her shop into these categories:

- Operational — Examples: Guest Intake, Workflow Practices, Opening & Closing the Shop

- Management & Team — Examples: Leadership Chain, Role Definitions, Hiring Documents

- Training & Development — Examples: Defined Expectations, Defined Provisions, How to Access Training

- Advertising & Marketing — Examples: All Contacts, Budget, Logo, Font, Imaging

- Finance — Examples: Payroll Process, Raises & Rewards, Document Filings

- Supply Chain — Example: Prefered Parts Vendors, Office Supplies, Returns & Cores

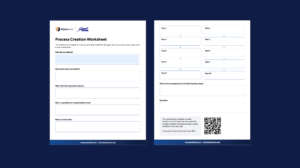

- Document every single process.

Each process should have a title, what it’s for and who it’s for, and then clear steps to execute that process. Lola provides a free worksheet to help you document your processes. You can find the worksheet here.

- Stand by your processes.

Defining processes is an empty effort if you do not enforce them with your team. Define the processes, document them, and then stick to them and hold your team accountable for sticking to them. You’ll thank yourself for it.

To learn more in-depth insights into process creation for your auto shop and what processes Lola recommends getting started with, watch the on-demand version of Lola’s webinar today and download the free process creation worksheet.

Webinar Q&A Follow Up

We received many excellent questions during the webinar, and we were not able to address them all during the live session. Lola graciously took the time to answer each question below:

Do you have any tips and advice for starting hard conversations with employees (ex, disciplinary, performance, termination)?

Before having these conversations, it’s essential to know where you stand. Reference the processes that employees have signed off on. For example, if it’s a disciplinary conversation, direct them back to the standards they agreed to. Remind them of their commitments to help them get back on track or exit if necessary.

What tool or platform do you use to house all your process docs so the entire team can access them? Do you use a binder? Google Drive?

We use a Microsoft shared drive and have printed and bound copies available at the front desk, manager’s office, and back of house.

Do you allow employees to work on their or friends’ cars after hours?

Employees can work on their own cars after 60 days of working at the shop. They can also work on their spouses’, significant others’, or parents’ cars, but not on extended family or friends’ cars. They must notify us and have another person in the shop with them to avoid liability. I’m not trying to come into a squished technician one day.

How important are daily huddles with your team, and what should be discussed?

Daily huddles are crucial for team alignment. Every morning at 7:50, Jake, who runs our service, meets with the technicians to set expectations, review the previous day’s performance, give shoutouts, and discuss upcoming training or events. If an issue arises, we address it immediately with our “See it, Say it” policy to prevent lingering problems.

Who do you use for CRM/marketing?

Our CRM is managed by AppFueled, which handles our app, website, and all CRM functions. We have marketing in-house. We also work with Auto Ground for SEO placement on Google.

How many technicians do you have currently?

We currently have three full-time technicians and space for two more.

Do you have a process for what reporting and benchmarks you are looking at and monitoring in Tekmetric?

I monitor various metrics daily, weekly, and monthly and review everything quarterly. Daily checks include discovered sales, sold sales, and parts margins. I delve deeper into these metrics weekly and monthly; I assess profits, warranties, guest count, hours turned, and more.

How are you dealing with disciplinary actions/terminations during a technician shortage?

I am always hunting for new talent and remain active on hiring boards. Despite the technician shortage, we simply do not allow our shop and business to be compromised. Recently, we let go of two technicians: one for not following the inspection process and another for causing internal strife.

I am also process-driven, and micromanagement has come up. How do you ensure processes are followed consistently at the moment rather than fixing mistakes after the fact (especially when working remotely)?

I watch from a distance a lot. I can see what’s happening in my reporting and listening to phone calls. If I notice drops in certain areas, I start investigating.

I’m buying a well-established shop that has no systems in place, no software, and no social presence. What should I focus on in the first 3-6 months?

If it was me, first, secure your social media presence and ensure your website looks good. Identify key reports and establish cash flow management. Implement new software immediately to avoid switching systems later.

I’m a new shop owner and struggling to get my team to keep the shop clean. Do you have any advice?

Consider having a team cleaning day to set cleanliness expectations. We do an annual deep clean of the shop, which helps everyone understand their responsibilities and maintain standards.

What about non-compete clauses?

I don’t hold anyone to that. If you create a solid environment, people won’t need to look around.

How about your training plan? Do you rely on internal training or have third-party trainers?

We ensure all our techs undergo comprehensive training to bridge any knowledge gaps.

We use online, onsite, and parts shop training, dedicating 40 hours a year per person.

Can you tell me the hybrid pay plan?

Each of our techs is paid based on skills and certifications. Everyone has a base livable wage and a tiered incentive to flag more hours.