Your auto repair shop’s time is worth something, which is why your business relies on efficiency to succeed — every minute counts.

Inefficiencies steal precious time from revenue-generating activities in your shop and hinder growth and expansion opportunities. Plus, inefficiencies that slow down the completion of jobs negatively impact the customer experience of folks who just want their vehicle back.

One top habit in the healthiest auto shops is the conscientious tracking of operational analytics — including those related to overall shop efficiency. Monitoring efficiency-related metrics provides valuable insights into areas where your shop loses time. By being aware of areas of inefficiency, you can take strategic action to make a change.

“Technician efficiency” often emerges as a key performance indicator, along with related metrics such as “technician productivity” and “technician performance.” Anything that leads to technician downtime is undesirable. One particular source of inefficiency can obstruct even your most efficient technician from starting to work on a job — Parts ordering.

The Parts Ordering Process Is Riddled With Friction Points, Making It A Major Contributor To Inefficient Operations

We surveyed over 400 shops across the U.S., and here are the top challenges they encounter when ordering parts:

Can you identify with any of these parts ordering challenges?

- Determining parts availability and getting the part fast

- Identifying the right part number

- Getting the best price

- The time it takes to place parts orders

At the end of the day, parts ordering challenges impact your shop’s efficiency. They trickle down to delay your technicians’ ability to start a job. They cap your shop’s daily work order capacity. They impede your ability to meet customers’ expectations to get their car back fast. And they block revenue-growing opportunities.

How long is it taking your shop to order parts? Do you wish it was faster?

What Would Saving 5-15 Minutes Per Repair Order Mean For Your Shop’s Efficiency Goals?

Here’s a fact from the same survey of over 400 shops: The average shop using PartsTech saves 5-15 min per repair order. How do they achieve this?

Instead of making endless phone calls or navigating multiple websites to check parts availability and pricing, shops using PartsTech find and order parts in one place.

PartsTech simplifies the parts ordering process by consolidating all your preferred parts and tire suppliers into one user-friendly online platform. You set up your preferred suppliers in PartsTech, and you’ll have one search bar and a single screen to get the right part(s) fast.

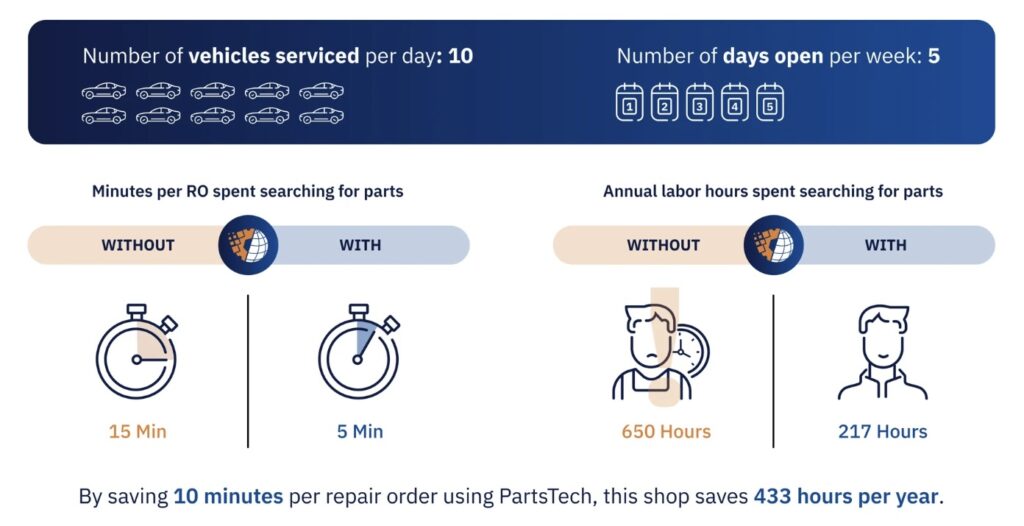

Saving 5-15 Minutes Per Work Order Might Seem Inconsequential, But The Cumulative Effect Is Significant

Minutes saved ordering parts can translate into hundreds of hours per year. Take a look at an example scenario in the image below:

By reducing time spent ordering parts, you create free time for initiatives that boost revenue and help you achieve your shop’s unique goals.

Take a look at the chart below and calculate how much time your shop could save by changing how you order parts:

Less Time On Parts, More Time On Revenue-Boosting Initiatives

If you had the extra time you calculated above, what’s the first thing you’d do with that time?

PartsTech customer Gomez Auto Repair spends their time savings calling customers to get them back in for repeat business:

“By saving 2-3 hours a day using PartsTech, we are able to call our customers to get them back into the shop for their maintenance and ultimately boost our profitability and car count.”

Stephen Leal, General Manager, Gomez Auto Repair (Watch Full Story)

The possibilities of how you could reallocate time are endless, and your choice depends on your shop’s individual objectives. Here are some ideas to give you a kickstart:

Other Ways To Reallocate Time

Sometimes, the most valuable reallocation of time savings is not tied directly to growth and revenue opportunities. Instead, it is centered on indirect benefits, such as nurturing your employees’ (or your own) well-being and career development. To explore this aspect further, check out our blog post on how to use time savings to attract and retain technicians and invest more in yourself – click here.